- 100% fresh air

- Reduced Energy use

- Spot cooling

- Filtered air

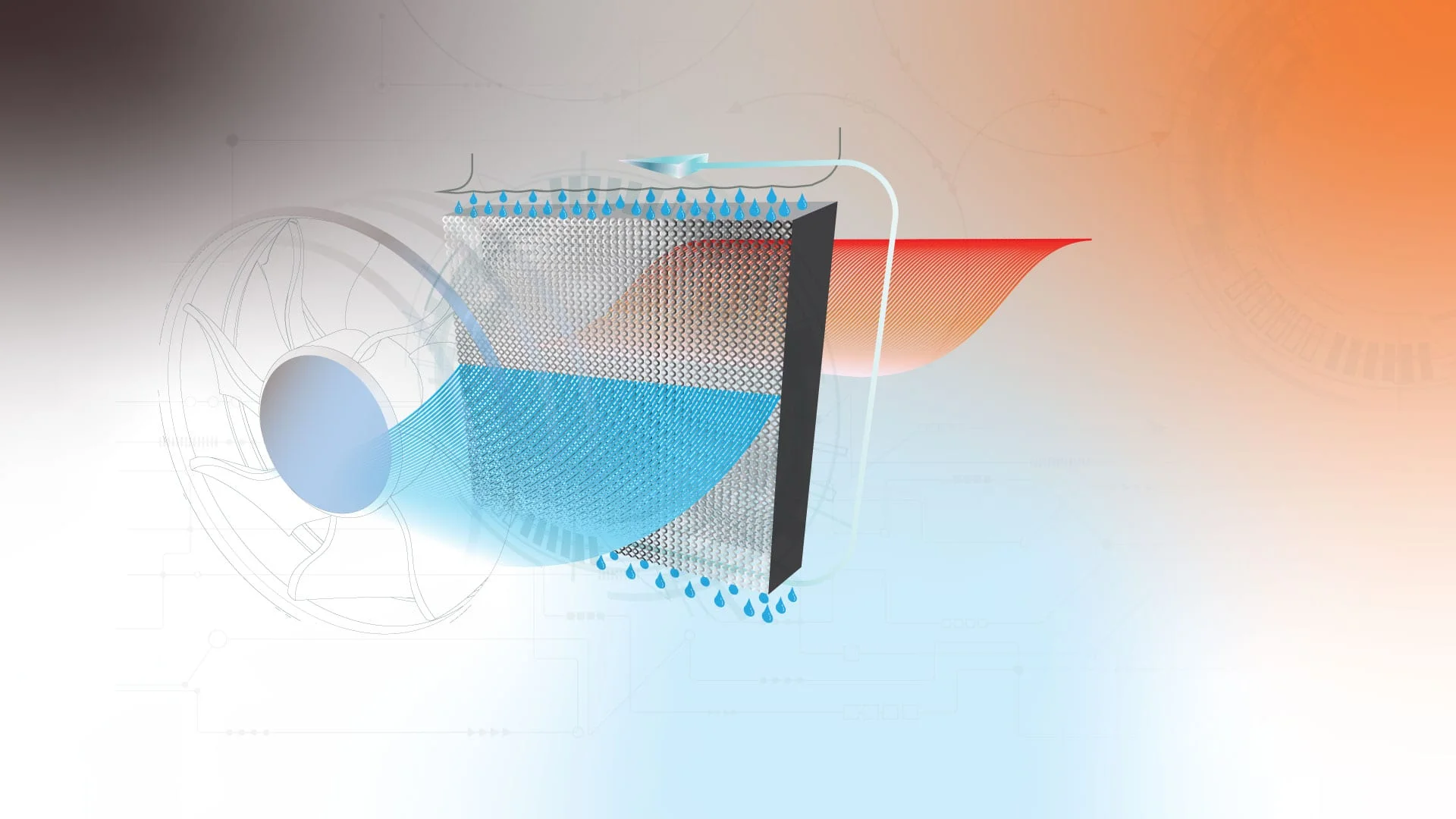

Direct Evaporative Cooling

Breezair evaporative cooling uses evaporation to cool the air. Based on the principles of evaporation, hot and dry outside air is drawn through water-soaked cooling pads. As the air is pulled through these pads, the water evaporates and the heat in the air is absorbed, which lowers the air temperature. A fan then pushes the cool air throughout the building via a network of ducts.

The key to effective evaporative cooling is to ensure saturation of all cooling pads during operation and to size and design the system’s fan and motor to deliver the appropriate airflow for the space.

Evaporative cooling describes this natural phenomenon, however, there are many other terms that we might hear with the same meaning including evaporative air conditioning, adiabatic cooling, ducted evaporative cooling, swamp coolers, and desert coolers.

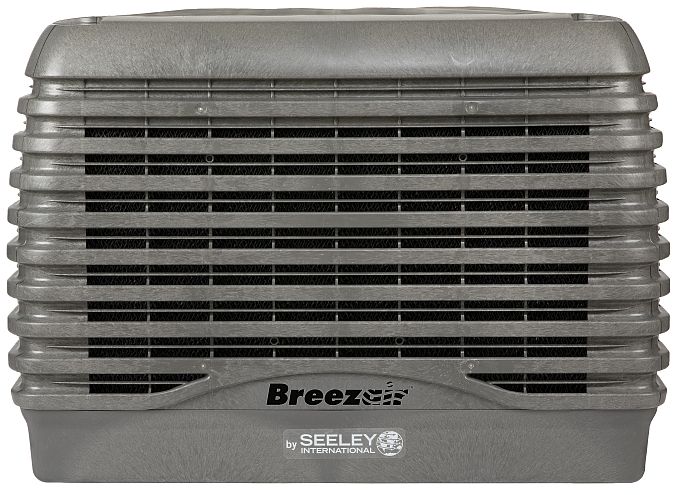

Breezair solution

Breezair by Seeley International offers full series of high performing and world leading direct evaporative coolers.

Whether you need cooling for medium or large commercial applications, industrial plants or in general large areas, award winning Breezair brand provides uncompromising safety, reliability, comfort and energy-efficiency. Seeley International never stops striving to innovate and build the world’s most energy efficient products: evaporative cooling is fast becoming the most efficient option when cooling large or open-air spaces.

How does Breezair evaporative cooling work?

As said before, Breezair evaporative cooling uses evaporation to cool the air.

Hot air enters the cooling unit on the roof where it is filtered and cooled as it passes through specially designed moistened Chillcel™ pads. As the air passes through the cooling pads, the water evaporates and the heat in the air is absorbed, which lowers the air temperature. Finally, a fan pushes the cool air throughout the building via a network of ducts.

key benefits of Breezair

100% fresh air

The evaporative cooling process relies on airflow, with cool air entering through ducts and then exiting via open doors or windows or extract fans. For this reason, only 100% fresh air is circulating, rather than stale and recycled air.

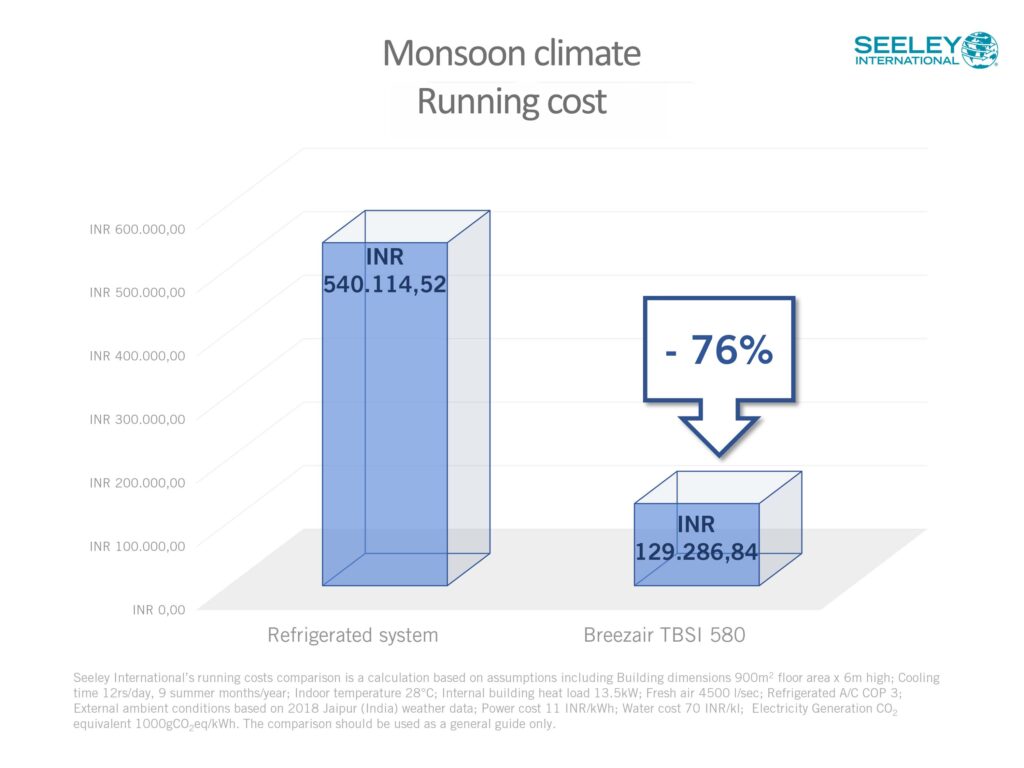

Reduced Energy use

No high electrical demand charges even in hot weather. Reduce the energy use and improve the cooling performance of existing refrigerated systems (when installed in pre-cooling or supplementary cooling). Total cooling performance increases when air temperature rises.

Spot cooling

Often commercial or industrial buildings have small spaces that are hot and uncomfortable to work in (because of heat from machines for example). In these cases, Evaporative Cooling can blanket the hot spot with a flow of cool, high velocity, fresh air, designed to positively impact your workers whenever they are in that hot location.

Filtered air

As the fan draws outside air through the cooling pads, this air is not only chilled but also filtered from impurities.

Cooling Performance

Breezair TBS 580 Supercool

This is the best evaporative cooler . The high cooling performance is achieved due to its design and use of the patented Mini Chillcel Pads, which makes it ideal for the hot summers in India, where every degree of cooling is important.

The unit is fully automatic and handles water management, self-cleaning, humidity control and also temperature control. More than 100 units can be controlled using the touch screen controller making it simple to control.

Breezair and the environment

Reduced greenhouse gas emissions

Evaporative cooling uses water to cool. This helps reduce the production of greenhouse gases, including harmful hydroflourocarbons.

Energy efficient

Better for your pocket and for the environment. We have estimated that in a location like Madrid (Spain) using Breezair you can reduce running costs up to 86%1 and carbon emissions up to 90%2.

Minimal water usage

The technologically advanced water management system continuously checks the quality of the water in your cooler. The system automatically replaces the water when mineral deposits exceed an acceptable level. The optimal result: minimum water use for maximum, fresh cooling power. Furthermore, you can generate your own cooling medium by rain water harvesting and to create a water neutral solution, you can use the waste water for grey, fire or irrigation.

Breezair Blowing Air

Breezair-components

Breezair Applications

Breezair TBS 580 Supercool

Applications

Factories

Factories are the most common place where you can install evaporative cooling. They are usually big areas where production machines can also produce a significant amount of heat.

Applications

Warehouses

Commercial buildings are very hard to cool with traditional air conditioning, because of their physical size. Warehouses are usually not conditioned at all: this can impact negatively for some stored goods (perishable foods, and pharmaceuticals) and also for the productivity of the staff working there.

Applications

Garages and car workshops

Garages and vehicle testing centres are usually semi-open hot spaces, & the air is full of vehicle exhaust emissions. Again, these open spaces cannot be cooled using conventional air conditioning, but working conditions can be challenging and definitely unhealthy. These areas are easy to cool with evaporative cooling, as they are usually high buildings where simple ducting is required.

Applications

Sport centers: paddle, tennis, climbing gyms

Gyms are needed to be kept cool and ventilated to prevent the buildup of CO2, besides the fact that tennis, basketball and volleyball players would not mind a cool and ventilated space where to play in Summertime and during heat waves.

Applications

Outdoor areas: terraces, tents, outdoor dining areas

Outdoor areas have no walls to contain the cool air: these spaces would be impossible to cool using conventional air conditioning because that type of system relies on recirculating the air of a sealed space. The problem can be solved by using evaporative air coolers like Breezair, which can easily supply a flow of fresh and cool air to those areas, since all the air is naturally exhausted all the time.

Applications

Schools, offices, educational centers

We have supplied evaporative cooling solutions in many educational centers. Children spend a large portion of their day indoor at school: ensuring that schools are ventilated and have good Indoor Air Quality is critical to protecting and supporting the health and wellbeing of students and teachers. All Seeley International evaporative cooling products increase ventilation by acting on the fresh air portion of an AHU or directly supplying outside air into the space.

Applications

Data centers and telecom

Indirect evaporative cooling can be perfect for cooling data centers and telecoms. These applications normally require continuous cooling throughout the day and a significant amount of power. But there is an even for efficient technology now in the planet that can reach lower temperatures than pure indirect evaporative cooling…that is M-cycle Indirect Evaporative cooling! This patent by Seeley International can cool below the wet-bulb temperature of outside air, not adding moisture to the air.

FAQs-Breezair

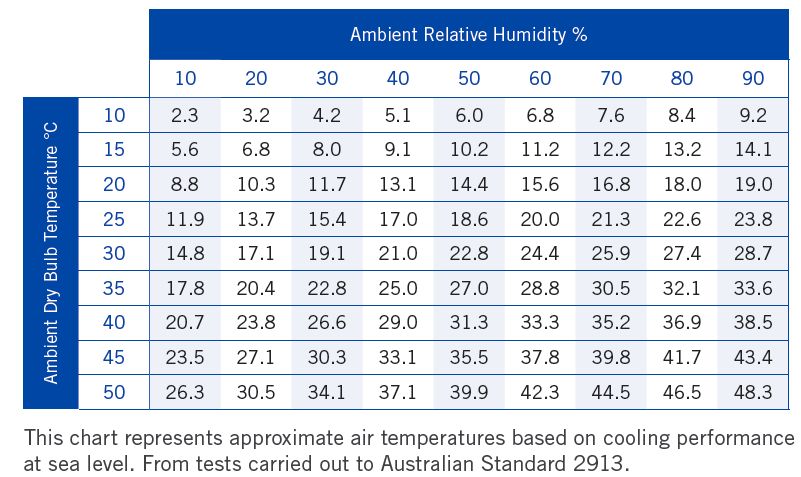

That depends on the temperature and humidity of the outside air (the ambient temperature). Have a look at the temperature chart below and you will see the answer. For example, at a temperature of 25 C and a relative humidity of 50% the air from a Breezair Evaporative Air Conditioner will be at 20 C, i.e. a 5 C drop. Or, at a temperature of 35 C and a relative humidity of 30% the air from the Cooler will be 25 C, i.e. a 10 C drop.

Yes, because they are simple machines. Those with V-belt drives need the drive system checked and adjusted once a year. Otherwise you need to check and clean the cooling pads regularly, depending on the level of pollution in the environment – at least every 6 months. In clean locations, once a year is enough. Clean cooling pads mean highest cooling performance and that is what you want. Check the water tank (reservoir) once a year and clean out if necessary. Follow the Owner’s Guide book.

The amount of water used is directly proportional to the amount of cooling being supplied — more water used, more cooling supplied. The water consumption is also affected by the humidity of the day — more humidity, less water used. It also depends on the setting of the machine — high speed operation uses more water. And finally, it depends on the Bleed setting. As a guide we can advise that, at minimum Bleed setting and at high speed setting and at a Relative Humidity (RH) of 30%, the water usage is about 7 Litres/hr per 1000 m3 /h (600cfm) of air flow. At a Relative Humidity (RH) of 50% the rate is about 5 Litres/hr per 1000 m3 /h air flow. For example, a TBA550 has an air flow of 10800 m3 /h at 80 Pa so it will use about 76 Litres/hr at 30% RH and about 54 Litres/hr at 50% RH.

Yes it does. The hot dusty air from outside is cleaned as it passes through the wetted cooling pads, where airborne particles are trapped by the cooling pads and many smaller impurities such as pollens and pollution are also reduced.

- Often, in large industrial buildings there are locations within the building where the heat is concentrated for a variety of reasons. You don’t need to air condition the whole building, you only need that spot to be more comfortable. It might be a furnace operation, or a part of a painting process, or a concentration of people, or a cluster of injection moulding machines. Spot Cooling by Breezair can dramatically improve the conditions in that location and improve your productivity and cost you much less than installing conventional air conditioning.